|

Anping Shuang Hao Filter Equipment Co.,Ltd

|

Filter

| Price: | 1.0~200.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

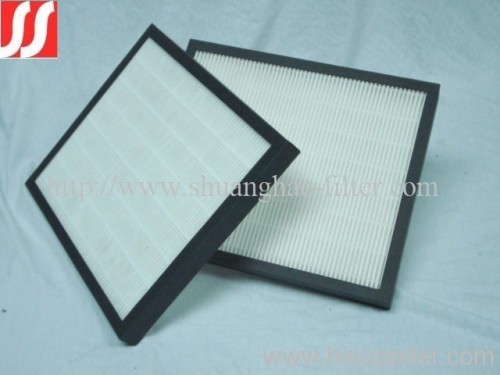

High efficiency filter is mainly used for filtering the air of suspended particles less than 0.3um, as the end of the various filtration systems

Description:

1. High efficiency filter is mainly used for filtering the air of suspended particles less than 0.3um, as the end of the various filtration systems filter.

◆ Applications:

Widely used in electronics factory, semiconductor, precision machinery, pharmaceuticals, hospitals, food industry, cleanliness requirements of the high pay of civil or industrial cleaner plant by the end of the filter.

◆ Structure:

Used to filter ultra-fine glass fiber filter paper to the plastic sheet of paper, folded aluminum foil board and other materials for the separation, the new polyurethane sealant for sealing, galvanized plate, stainless steel, aluminum alloy for the frame, then each undergo a rigorous test .

◆ Material:

Thin glass fiber, PP and efficient paper.

◆ Related knowledge filter:

By different particles, high efficiency filter up to 99.99%. It was the total efficiency of the filter and clean room grade level corresponding to up, as if with a number of ultra-high efficiency filter 9 can reach 100 degrees or even 10 levels of clean. In fact, this is a wrong concept. High efficiency filter is the core of the system, but not the only condition to ensure cleanliness. High efficiency filter is a necessary condition to meet the requirement, one of the most easy terms. To achieve the appropriate level of clean room should also have a number of necessary conditions, such as wind speed, air changes, doors and windows closed, and out of clean room personnel control many aspects. Only full compliance in these areas can ensure the cleanliness of clean room requirements. Filter manufacturer is only responsible for compliance. Any person or manufacturer does not dare to say: you use the filters I can achieve so many levels!

2. In effect blocking the main bag filter dust particles 0.5um and above, with the filtering area, dust capacity, low resistance to repeated use of the advantages of cleaning.

◆ Applications:

Bag filters are widely used in central air conditioning and ventilation systems, pharmaceuticals, hospitals, electronics, food and other industrial cleaning, the filter can be as efficient front-end filter, high efficiency air filters to reduce the load. To extend it's service life. As the wind bag filter area, so it's large dust capacity, low wind speed, is considered the best in the current structure of the filter effect

◆ Structure:

Using the new composite non-woven or fine glass fiber and synthetic fiber imports plus coated reinforcement forming filter, bag style, with various metal frame (galvanized steel, aluminum, aluminum profile)

◆ Material:

Filter is used generally three types of composite non-woven, synthetic fiber and glass fiber imports.

◆ Filter of knowledge related to:

Bag filter is essential for normal ventilation and air conditioning systems. It is the main force filtering. Bag made primarily to meet the wind volume, low-resistance requirements. Strictly speaking, the front-end filter bag should have a layer of pre-filter, the general use of disposable paper filter plate frame or metal frame. However, some domestic users of paper in front of the filter to achieve life after box is not directly used in the replacement of bag filters for the first stage filter, resulting in appalling conditions used bag filter, shortened life expectancy, manufacturers can not meet design requirements. This situation should be avoided, although the increase in a pre-filter increases the cost of a purchase, but can be extended filter bag replacement cycle, long term, but overall lower maintenance costs.

3. Initial efficiency filters generally Kam convex mesh filter (nylon net) non-woven, glass fiber as the filter, folding wedge shape to increase the filtration area, clamping or the built-in metal wire mesh support dragon skeleton , together with the metal frame, made of plate structures. With resistance, long life, washable, durable and so the economy.

◆ Applications:

Generally used for central air conditioning and ventilation systems focus on pre-filter, gas turbine and air compressor pre-filter.

◆ Structure:

Filter structure is generally divided into dragon skeleton and the skeleton frame. Dragon skeleton is characterized by strong, filter distribution, but the production time consuming. Box frame features easy to replace filter media to produce time-intensity slightly worse than the dragon skeleton.

◆ Material:

The non-woven fabrics can be washed, activated carbon, synthetic fiber, chemical fiber (imported), glass fiber (imported), Kam-convex mesh (nylon net). The most common is the non-woven glass fiber. Efficiency can be coarse or medium effect.

◆Relevant knowledge introduction:

Used early coarse filter material for metal frame giving the impression that quite some Chinese characteristics. Theoretically, one-time choice of filter paper with the same frame, made of durable metal frame is mainly due to cost savings. The use of metal frame, when to filter life, just replace the filter inside can be, and therefore cost savings.

Limited to the structure and cost reasons, the metal frame coarse filter for general use of non-woven filter. But one thing to note is that some users are always asked to wash the filter manufacturers use the filter material. In principle, any filter material once they have been rinsed with water (including washing), the filter performance is compromised, so all the bad arguments, will directly lead to a serious scrap the filter. Some filters can be used even if the washing is to seriously reduce the cost of filtration efficiency. The results did not at the expense of prolonging the life of filter performance for this Banded approach is to use the correct replacement filter.